High-Quality Silicon Carbide Products | Advanced Ceramic Solutions

PRODUCT PARAMETERS

Description

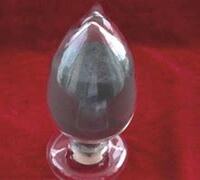

Overview of Silicon Carbide Powder

Silicon carbide (SiC) powder is a high-performance ceramic material composed of silicon and carbon. Known for its exceptional hardness, thermal stability, and wear resistance, SiC powder is widely used in abrasives, cutting tools, refractory materials, and advanced technological applications like semiconductors and electric vehicle components.

Features of Silicon Carbide Powder

Exceptional Hardness: One of the hardest known materials, second only to diamond, making it ideal for abrasive and cutting applications.

Thermal Stability: High resistance to thermal shock and can withstand extreme temperatures, enhancing its utility in refractory and high-temperature environments.

Chemical Inertness: Resistant to most chemicals, including acids and alkalis, ensuring durability in harsh conditions.

Wear Resistance: Excellent wear resistance properties make it suitable for demanding mechanical applications.

Electrical Conductivity: Depending on the purity and doping levels, SiC can exhibit varying degrees of electrical conductivity, useful in electronics.

(L Whole High Purity Green Silicon Carbide Powder Abrasive Refractory for Kiln Application Mgo Sio2 Materials)

Specifications of L Whole High Purity Green Silicon Carbide Powder Abrasive Refractory for Kiln Application Mgo Sio2 Materials

This L Whole High Purity Green Silicon Carbide Powder is designed for demanding applications. It serves as both an abrasive and a refractory material. Its main use is in kiln linings for MgO-SiO2 based materials. High purity is critical for this application.

The powder boasts exceptional purity levels. It minimizes unwanted impurities. This purity ensures consistent performance. It prevents contamination of the materials being processed. The particle size distribution is tightly controlled. We offer various standard mesh sizes. This allows for precise matching to specific kiln lining requirements. You can choose the best fit for your process.

Green silicon carbide is very hard. It ranks just below diamond and boron carbide. This hardness provides excellent wear resistance. It helps the refractory lining last longer under harsh conditions. The powder has high thermal conductivity. It also has low thermal expansion. These properties are vital in kilns. They help manage heat stress. They reduce the risk of cracking or spalling.

Chemical stability is another key feature. The powder resists attack from many substances. This includes various slags and fluxes. This resistance protects the kiln lining integrity. It maintains the purity of the MgO-SiO2 materials being fired. The powder performs well at high temperatures. It withstands the intense heat inside industrial kilns.

Using this powder improves kiln efficiency. It contributes to longer refractory life. This reduces downtime for repairs. It also helps maintain product quality. The consistent specifications ensure reliable results batch after batch.

(L Whole High Purity Green Silicon Carbide Powder Abrasive Refractory for Kiln Application Mgo Sio2 Materials)

Applications of L Whole High Purity Green Silicon Carbide Powder Abrasive Refractory for Kiln Application Mgo Sio2 Materials

L Whole High Purity Green Silicon Carbide Powder is a top-grade material. It is very hard. It stays strong even at very high heat. This makes it perfect for tough jobs. One key use is as an abrasive. The powder cuts and shapes things well. It grinds down surfaces smoothly. It polishes materials to a fine finish. This is needed in making tools and parts. Another big use is in refractories. Refractories line hot places like kilns. They must handle extreme temperatures. Adding this powder makes refractories better. It improves their strength. It helps them resist damage from heat and chemicals. This extends the life of kiln linings. It saves money on repairs. This powder is especially good for kilns using MgO-SiO₂ materials. These are magnesia-silica refractories. The silicon carbide powder works well with them. It bonds effectively to the MgO-SiO₂ base. This creates a stronger, tougher lining. It protects the kiln structure better. The high purity means fewer impurities. Impurities can weaken materials. Pure powder gives consistent results. It ensures reliable performance every time. Industries count on this for their kilns. The powder helps maintain high temperatures safely. It supports efficient kiln operation. Factories need dependable materials. This powder delivers that dependability.

Company Introduction

Welcome to It-Chuiko, a premier international supplier of high-quality silicon carbide powder and silicon carbide ceramics. Our products are renowned for their exceptional hardness, thermal stability, and wear resistance, making them ideal for abrasives, cutting tools, refractory materials, and advanced semiconductor applications. We serve a diverse range of industries, including automotive, aerospace, and electronics, with a commitment to quality and innovation. With state-of-the-art production facilities and rigorous quality control, we ensure that our customers receive superior products tailored to their specific needs. Partner with us for reliable, high-performance materials that drive your business forward.

If you have any questions, please feel free to contact us(nanotrun@yahoo.com).

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of L Whole High Purity Green Silicon Carbide Powder Abrasive Refractory for Kiln Application Mgo Sio2 Materials

Green silicon carbide powder is a top choice for kiln linings. Why is it so popular? It’s very pure. This purity means fewer impurities weaken the material. It withstands extreme heat well. It keeps its shape under high temperatures inside kilns. This makes linings last much longer.

How does it help the refractory mix? It makes the mix stronger. It bonds well with magnesium oxide and silica. This creates a tougher, more stable lining material. The lining resists cracking better. It handles the stress of heating and cooling cycles effectively.

What grain sizes work best? Fine powders are common. They blend smoothly into the refractory mix. This ensures even distribution. Consistent mixing gives uniform properties throughout the lining. Coarser grains might be used sometimes. This depends on the specific application needs.

How much powder should be added? The right amount is critical. Too much can cause problems. It might make the lining brittle. Too little won’t give the full benefit. Follow the supplier’s guidelines closely. Their advice is based on proven results. Stick to their recommended ratios.

Is it safe to handle? Handle it carefully. Always wear protective gear. Use gloves and a dust mask. Breathing in fine dust is harmful. Avoid skin contact where possible. Keep the work area clean. Proper handling prevents health issues.

(L Whole High Purity Green Silicon Carbide Powder Abrasive Refractory for Kiln Application Mgo Sio2 Materials)

REQUEST A QUOTE

RELATED PRODUCTS

Silicon Carbide 90% Deoxidizer Silicon Carbide Lump/powder Metals & Metal Products

SIC Silicon Carbide Powder Ceramic Abrasives in Grit Shape for Grinding Blasting Cutting

Factory silicon carbide powder

green silicon carbide sic powder 1200 grit for mixer casting blades

98.5% Sic Black Silicon Carbide Green Silicon Carbide 300 mesh silison carbide powder