High-Quality Silicon Carbide Products | Advanced Ceramic Solutions

PRODUCT PARAMETERS

Description

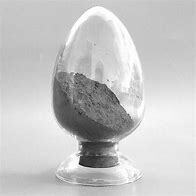

Overview of Silicon Carbide Powder

Silicon carbide (SiC) powder is a high-performance ceramic material composed of silicon and carbon. Known for its exceptional hardness, thermal stability, and wear resistance, SiC powder is widely used in abrasives, cutting tools, refractory materials, and advanced technological applications like semiconductors and electric vehicle components.

Features of Silicon Carbide Powder

Exceptional Hardness: One of the hardest known materials, second only to diamond, making it ideal for abrasive and cutting applications.

Thermal Stability: High resistance to thermal shock and can withstand extreme temperatures, enhancing its utility in refractory and high-temperature environments.

Chemical Inertness: Resistant to most chemicals, including acids and alkalis, ensuring durability in harsh conditions.

Wear Resistance: Excellent wear resistance properties make it suitable for demanding mechanical applications.

Electrical Conductivity: Depending on the purity and doping levels, SiC can exhibit varying degrees of electrical conductivity, useful in electronics.

(Best s silicon carbide powder for casting foundry silicon carbide powder Sandblasted silicon carbide 80 120 grit)

Specifications of Best s silicon carbide powder for casting foundry silicon carbide powder Sandblasted silicon carbide 80 120 grit

Best’s silicon carbide powder for casting foundries offers high-quality performance in demanding industrial applications. The product features sandblasted silicon carbide in 80-120 grit, ideal for surface preparation, metal casting, and abrasive processes. The grit size ensures consistent particle distribution, providing reliable results in precision tasks. This grade balances cutting power with smooth finish capabilities, making it versatile for multiple uses.

The powder is manufactured using advanced processing methods to guarantee purity and uniformity. Each particle is sharp-edged and durable, designed to withstand high-pressure environments. This toughness extends the material’s lifespan, reducing replacement frequency and operational costs. The angular shape of the grains enhances cutting efficiency, ensuring fast material removal during sandblasting or grinding.

Silicon carbide’s thermal stability makes it suitable for foundry applications. It resists extreme temperatures without degrading, maintaining performance in molten metal environments. The low thermal expansion coefficient minimizes cracking risks in molds or cores. This property ensures dimensional accuracy in cast parts, critical for industries like automotive or aerospace.

The 80-120 grit range is optimized for creating smooth yet detailed surface textures. It works well for cleaning metal surfaces, removing rust, or preparing substrates for coatings. The powder’s hardness (9.5 Mohs scale) outperforms traditional abrasives like alumina or glass beads. This hardness translates to faster processing times and reduced energy consumption.

Chemical purity is a key focus. The powder contains minimal impurities, ensuring no contamination during metal casting. It reacts predictably with molten alloys, improving casting quality and reducing defects. The material is also inert, posing no environmental or health risks when handled properly.

Packaging options include moisture-resistant bags to preserve product integrity during storage or transport. Custom batch sizes are available to meet specific project needs. The powder is compatible with standard blasting equipment, requiring no special modifications.

End-users report improved surface finishes and longer-lasting abrasive performance compared to alternatives. The product’s consistency reduces variability in production processes, supporting tighter quality control. Its reusability in certain applications adds cost-effectiveness over single-use abrasives.

Best’s silicon carbide powder meets industry standards for safety and performance. It is tested rigorously for particle size, chemical composition, and abrasion resistance. This ensures reliability in high-stakes industrial settings.

(Best s silicon carbide powder for casting foundry silicon carbide powder Sandblasted silicon carbide 80 120 grit)

Applications of Best s silicon carbide powder for casting foundry silicon carbide powder Sandblasted silicon carbide 80 120 grit

Best Silicon Carbide Powder offers reliable solutions for casting foundry operations. Its sandblasted 80-120 grit variant works well for surface preparation and material processing. Foundries use this powder to clean molds and remove residues from metal surfaces. The sharp edges of the grains ensure efficient cutting without damaging equipment. This makes it ideal for creating uniform textures on molds before casting.

The powder’s high hardness improves the durability of refractory coatings. Foundries apply it to linings to handle extreme heat during metal pouring. It reduces wear on furnace walls and extends their service life. This helps maintain consistent temperatures for better-quality castings. The thermal stability of silicon carbide prevents breakdown even under prolonged exposure to molten metals.

In sandblasting, the 80-120 grit size balances speed and finish quality. It removes rust, scale, or old paint from metal parts quickly. The particles break down slowly, allowing reuse over multiple cycles. This lowers material costs and waste generation. Foundries benefit from faster turnaround times and reduced downtime for maintenance.

The powder also enhances metal casting processes. Mixing it into molding sand increases resistance to thermal shock. This minimizes cracks or defects in finished products. Its uniform grain size ensures even distribution within the sand mixture. This results in smoother casting surfaces and fewer finishing steps.

Industries like automotive and machinery rely on this silicon carbide grade for critical components. It supports precision in parts requiring tight tolerances. The material’s inert nature prevents reactions with molten alloys. This preserves the chemical integrity of cast metals.

Best Silicon Carbide Powder adapts to various blasting equipment types. Its consistent particle size reduces clogging risks in nozzles and hoses. Operators achieve predictable results across different applications. The product meets industrial standards for purity and performance. This makes it a practical choice for foundries aiming to optimize efficiency and output quality.

Company Introduction

Welcome to It-Chuiko, a premier international supplier of high-quality silicon carbide powder and silicon carbide ceramics. Our products are renowned for their exceptional hardness, thermal stability, and wear resistance, making them ideal for abrasives, cutting tools, refractory materials, and advanced semiconductor applications. We serve a diverse range of industries, including automotive, aerospace, and electronics, with a commitment to quality and innovation. With state-of-the-art production facilities and rigorous quality control, we ensure that our customers receive superior products tailored to their specific needs. Partner with us for reliable, high-performance materials that drive your business forward.

If you have any questions, please feel free to contact us(nanotrun@yahoo.com).

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Best s silicon carbide powder for casting foundry silicon carbide powder Sandblasted silicon carbide 80 120 grit

What is silicon carbide powder used for in casting foundries?

Silicon carbide powder improves metal casting quality. It strengthens molds, resists high heat, reduces defects like cracks. Foundries add it to molding sand for better surface finish. The 80-120 grit size works for sandblasting, cleaning molds, preparing surfaces.

Why choose this silicon carbide powder over others?

This powder has high hardness, sharp edges. It cuts faster, lasts longer than alternatives. It handles extreme temperatures without breaking down. The 80-120 grit size balances cutting speed and finish quality. It works well for cleaning, deburring, surface prep in foundries.

How does the 80-120 grit size affect performance?

The grit size determines particle coarseness. 80-120 grit is medium-coarse. It removes material quickly but leaves a smoother finish than rougher grits. It’s ideal for general foundry tasks. Finer grits polish, coarser grits cut aggressively. This size offers a middle ground for efficiency.

Can this powder be reused in foundry applications?

Reuse depends on the process. After sandblasting, particles break down, lose effectiveness. In mold additives, reuse is possible if the mix stays uncontaminated. Check for fines or debris before reusing. Replace powder when cutting speed drops or defects increase.

What safety steps are needed when handling this powder?

Wear gloves, goggles, masks. Silicon carbide dust irritates skin, eyes, lungs. Use in ventilated areas to avoid inhaling particles. Store in sealed containers away from moisture. Dispose of used powder following local rules. Keep away from open flames—though it’s non-flammable, dust can pose explosion risks in high concentrations.

(Best s silicon carbide powder for casting foundry silicon carbide powder Sandblasted silicon carbide 80 120 grit)

REQUEST A QUOTE

RELATED PRODUCTS

Zhongci Ultra fine 6000# Black Silicon Carbide micron powder for ceramic sharpening stone

Factory of Silicon Carbide Powder with good quality/Black Carborundum powder

Industrial Graphite Electrode Block Pattern Carbon-Based Refractory Powder Silicon Carbide Granules High Performance Graphite

Refractory material sic sandblasting silicon carbide powder for

High purity industrial casting black silicon carbide powder green silicon carbide s whole