High-Quality Silicon Carbide Products | Advanced Ceramic Solutions

PRODUCT PARAMETERS

Description

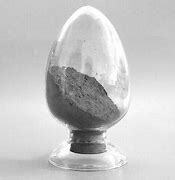

Overview of Silicon Carbide Powder

Silicon carbide (SiC) powder is a high-performance ceramic material composed of silicon and carbon. Known for its exceptional hardness, thermal stability, and wear resistance, SiC powder is widely used in abrasives, cutting tools, refractory materials, and advanced technological applications like semiconductors and electric vehicle components.

Features of Silicon Carbide Powder

Exceptional Hardness: One of the hardest known materials, second only to diamond, making it ideal for abrasive and cutting applications.

Thermal Stability: High resistance to thermal shock and can withstand extreme temperatures, enhancing its utility in refractory and high-temperature environments.

Chemical Inertness: Resistant to most chemicals, including acids and alkalis, ensuring durability in harsh conditions.

Wear Resistance: Excellent wear resistance properties make it suitable for demanding mechanical applications.

Electrical Conductivity: Depending on the purity and doping levels, SiC can exhibit varying degrees of electrical conductivity, useful in electronics.

(Reliable Silicon carbide wafer multi-wire cutting slurry )

Specifications of Reliable Silicon carbide wafer multi-wire cutting slurry

Reliable silicon carbide wafer multi-wire cutting slurry is essential for precise wafer slicing. This slurry contains sharp silicon carbide grains suspended in a liquid carrier. The grain size is critical. Consistent grain size ensures uniform cutting action. Smaller grains produce smoother wafer surfaces. Larger grains cut faster. Grain shape also matters. Angular grains cut more effectively than rounded ones. Grain distribution must be uniform throughout the slurry. Clumping causes uneven cutting. Sedimentation is bad. It leads to inconsistent slurry performance. The chemical composition of the carrier fluid is important. It must not react with the silicon carbide. It must not damage the wire. The fluid lubricates the cutting wire. It helps remove waste material. Viscosity needs control. Proper viscosity keeps grains suspended. It helps the slurry flow onto the wire effectively. Too thick slows cutting. Too thin provides poor support. The pH level must be managed. Extreme pH can harm the wire or the wafer material. A stable pH ensures consistent performance. Slurry concentration is another key factor. The ratio of silicon carbide to carrier fluid affects cutting speed and surface finish. Higher concentration usually means faster cutting. It can also increase wire wear. Finding the right balance is crucial. Continuous mixing during use prevents settling. Fresh slurry delivers the best results. This slurry helps achieve clean cuts and good wafer yields.

(Reliable Silicon carbide wafer multi-wire cutting slurry )

Applications of Reliable Silicon carbide wafer multi-wire cutting slurry

Silicon carbide wafer cutting slurry is essential for slicing these tough materials. The slurry helps the cutting wires do their job. It makes the cutting process smooth and efficient. This material is very hard. Cutting it cleanly requires special tools. The slurry is part of those tools.

Reliable slurry ensures the wafers are cut precisely. Precise cuts mean less wasted material. This saves money. The surface of the cut wafer needs to be very smooth. Good slurry helps achieve this smooth finish. A rough surface causes problems later. Smooth surfaces are critical for making good devices.

The slurry also helps the cutting wires last longer. Wires wear out during cutting. Using effective slurry reduces this wear. This means fewer wire breaks and less downtime. Production lines keep moving. Consistent cutting speed matters for large-scale manufacturing. Dependable slurry keeps the speed steady.

Factories need to produce many wafers quickly. Consistent slurry performance is key for high output. It helps meet production targets. The quality of the final wafer impacts the electronics built on it. High-quality slurry leads to high-quality wafers. These wafers are used in power electronics, LEDs, and electric cars. Demanding applications require perfect wafers. The right slurry helps make that happen.

Choosing the correct slurry affects the whole manufacturing process. It impacts yield, cost, and product performance. Manufacturers rely on proven slurry formulations. They need products that work every time. This trust is built on reliability. The slurry must perform under tough conditions. Cutting silicon carbide generates heat and pressure. The slurry has to handle this environment.

Company Introduction

Welcome to It-Chuiko, a premier international supplier of high-quality silicon carbide powder and silicon carbide ceramics. Our products are renowned for their exceptional hardness, thermal stability, and wear resistance, making them ideal for abrasives, cutting tools, refractory materials, and advanced semiconductor applications. We serve a diverse range of industries, including automotive, aerospace, and electronics, with a commitment to quality and innovation. With state-of-the-art production facilities and rigorous quality control, we ensure that our customers receive superior products tailored to their specific needs. Partner with us for reliable, high-performance materials that drive your business forward.

If you have any questions, please feel free to contact us(nanotrun@yahoo.com).

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Reliable Silicon carbide wafer multi-wire cutting slurry

Here are 5 common questions about reliable silicon carbide wafer multi-wire cutting slurry:

What is silicon carbide wafer cutting slurry?

It’s a special liquid mixture. We use it during multi-wire saw cutting. The slurry carries abrasive particles. These particles grind the silicon carbide ingot. This process slices it into thin wafers. Good slurry ensures clean cuts and smooth wafer surfaces.

Why is the particle size in the slurry important?

Particle size matters a lot. It controls how fast the cutting happens. It also affects the quality of the wafer surface. If the particles are too big, they cause scratches. If they are too small, cutting is too slow. Consistent particle size gives reliable results.

How does slurry viscosity affect the cutting?

Viscosity is how thick the slurry is. Proper viscosity holds the particles well. It keeps them spread out evenly. This prevents the particles from sinking. It ensures steady cutting performance. If the viscosity is wrong, cutting quality suffers.

Can we recycle the used slurry?

Yes, recycling is possible. It saves money. It reduces waste. Used slurry gets cleaned. Good particles get separated. Then we put them back into fresh slurry. Recycling keeps cutting costs lower. It’s also better for the environment.

What safety steps are needed for handling slurry?

Be careful with slurry. Wear gloves and goggles. Avoid skin contact. Avoid breathing it in. Store slurry in sealed containers. Keep it away from heat. Always follow the safety instructions. This protects workers. It prevents accidents.

(Reliable Silicon carbide wafer multi-wire cutting slurry )

REQUEST A QUOTE

RELATED PRODUCTS

Refractory Sic Silicon Carbide Refractories Carborundum Powder High Purity Silicon Carbide Powder

Silicon carbide high-temperature heating vacuum sintering furnace

certificate factory of green / black silicon carbide powder

Factory Nano Silicon Carbide Sic powder silicon carbide Raw Material With 99% Purity

Low of silicon carbide powder black green 98% purity SiC powder with Grit / Fine powder