High-Quality Silicon Carbide Products | Advanced Ceramic Solutions

PRODUCT PARAMETERS

Description

Overview of Silicon Carbide Powder

Silicon carbide (SiC) powder is a high-performance ceramic material composed of silicon and carbon. Known for its exceptional hardness, thermal stability, and wear resistance, SiC powder is widely used in abrasives, cutting tools, refractory materials, and advanced technological applications like semiconductors and electric vehicle components.

Features of Silicon Carbide Powder

Exceptional Hardness: One of the hardest known materials, second only to diamond, making it ideal for abrasive and cutting applications.

Thermal Stability: High resistance to thermal shock and can withstand extreme temperatures, enhancing its utility in refractory and high-temperature environments.

Chemical Inertness: Resistant to most chemicals, including acids and alkalis, ensuring durability in harsh conditions.

Wear Resistance: Excellent wear resistance properties make it suitable for demanding mechanical applications.

Electrical Conductivity: Depending on the purity and doping levels, SiC can exhibit varying degrees of electrical conductivity, useful in electronics.

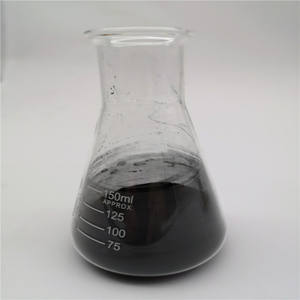

(Abrasives black silicon carbide silicon carbide nanoparticles Black Silicon Carbide Powder for grinding)

Specifications of Abrasives black silicon carbide silicon carbide nanoparticles Black Silicon Carbide Powder for grinding

Black silicon carbide powder is a manufactured abrasive material. It includes silicon carbide nanoparticles. This powder is really difficult. It is harder than a lot of materials. Individuals utilize it for grinding. They also use it for brightening and lapping. The particles are sharp. They reduced well. The powder comes in various sizes. You can obtain rugged grits. You can get fine grits. You can get additional great grits also. The nanoparticles are very tiny. They benefit extremely fine polishing jobs.

This product is tough. It withstands wear. It lasts a long time. It works well on difficult things. It grinds glass easily. It grinds rock quickly. It grinds ceramics easily. It grinds steels as well. It is good for removing material quick. It is good for making smooth surface areas. The powder has high thermal conductivity. It does not get as well hot quickly. This helps in some grinding jobs.

The powder is chemically steady. It does not react conveniently. It operates in various conditions. It is strong against acids. It is strong versus bases. It is strong versus oxidation. Individuals utilize it in bound abrasives. They use it in coated abrasives. They utilize it in loose unpleasant applications. It is common in grinding wheels. It prevails in sandpaper. It is common in blowing up media.

This black silicon carbide powder is pure. It has reduced levels of other components. This makes it do much better. The shade is dark. This comes from the manufacturing process. The particles have sharp sides. This helps them reduce much better. They crack well. This develops brand-new reducing edges. The powder is cost effective. It supplies good worth for the performance. It is a prominent choice for commercial grinding needs.

(Abrasives black silicon carbide silicon carbide nanoparticles Black Silicon Carbide Powder for grinding)

Applications of Abrasives black silicon carbide silicon carbide nanoparticles Black Silicon Carbide Powder for grinding

Black silicon carbide is a strong unpleasant material. People make it in high-temperature heaters. It has sharp edges and cuts well. It works helpful for grinding and cutting. This product handles laborious.

Lots of industries make use of black silicon carbide powder. It grinds steels like steel and iron. It shapes porcelains and glass. It also deals with rock and concrete. The powder comes in different dimensions. Crude grains remove product quick. Great grains make smooth finishes.

Black silicon carbide cuts much faster than various other abrasives sometimes. It remains sharp much longer. This conserves time and money. It generates much less heat during grinding. This helps avoid damaging the work surface. It is good for both hand tools and machines.

Black silicon carbide nanoparticles are really little. These little particles polish surface areas extra smooth. They function well for accuracy optics. They are also used in sophisticated porcelains. Nanoparticles make finer finishes possible.

This abrasive product is tough. It manages hefty grinding stress. It stands up to damaging down. This makes it trusted. Employees utilize it for grinding wheels, sandpaper, and blowing up media. It is a prominent choice for lots of tough jobs.

Company Introduction

Welcome to It-Chuiko, a premier international supplier of high-quality silicon carbide powder and silicon carbide ceramics. Our products are renowned for their exceptional hardness, thermal stability, and wear resistance, making them ideal for abrasives, cutting tools, refractory materials, and advanced semiconductor applications. We serve a diverse range of industries, including automotive, aerospace, and electronics, with a commitment to quality and innovation. With state-of-the-art production facilities and rigorous quality control, we ensure that our customers receive superior products tailored to their specific needs. Partner with us for reliable, high-performance materials that drive your business forward.

If you have any questions, please feel free to contact us(nanotrun@yahoo.com).

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Abrasives black silicon carbide silicon carbide nanoparticles Black Silicon Carbide Powder for grinding

Black silicon carbide powder works well for grinding. People often ask questions about it. Here are five common ones.

What is black silicon carbide powder? It is an abrasive material. Manufacturers make it from quartz sand and petroleum coke. They heat these materials together in an electric furnace. The result is a very hard, sharp powder. This powder is excellent for grinding tough surfaces.

Why is it black? The color comes from impurities. These impurities are present in the raw materials used. Iron and aluminum are common impurities. They give the powder its dark color. This doesn’t usually hurt its grinding performance.

What particle sizes are available? You can find many sizes. Fine grits go down to nanoparticles. Coarse grits are much larger. The size you need depends on your job. Finer grits give smoother finishes. Coarser grits remove material faster.

Is black silicon carbide hard? Yes, it is extremely hard. It ranks just below diamonds and boron carbide. This hardness makes it cut efficiently. It stays sharp longer than softer abrasives. This means it lasts well during grinding tasks.

What materials can it grind? It grinds hard materials effectively. Use it on glass, stone, ceramics, and certain metals. It works well on cast iron too. It is not the best choice for softer steels. Softer steels might clog the abrasive. Choose a different abrasive for those.

(Abrasives black silicon carbide silicon carbide nanoparticles Black Silicon Carbide Powder for grinding)

REQUEST A QUOTE

RELATED PRODUCTS

Sic Grit Polishing Powder Silicon Carbide Refractory Material Sandblasting Black Silicon Carbide

F1200 2-10um Microns 96% SiC Silicon carbide powder

Low of silicon carbide powder black green 98% purity SiC powder with Grit / Fine powder

Beta Grayish Green Cubic Superfine SiC Nanoparticle Silicon Carbide Powder for Polymer

Black Silicon Carbide Abrasive for Effective Polishing,Microparticle Powder Abrasive