High-Quality Silicon Carbide Products | Advanced Ceramic Solutions

Silicon Carbide Sharpening Rocks: What Grit Do You Really Required?

(what grit is silicon carbide sharpening stone from dans whetstone?)

Honing devices is crucial. Keeping edges eager makes job less complicated and more secure. Many products act as developing stones. Silicon carbide is a preferred choice. It provides distinct benefits. Yet comprehending grit is key. Grit refers to the rock’s coarseness. It affects just how quick product gets gotten rid of. It affects the last edge coating. This article checks out silicon carbide developing stones. We focus on grit selection. We cover what they are, why grit issues, just how to pick, applications, and typical concerns.

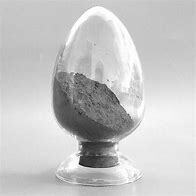

1. What is a Silicon Carbide Sharpening Rock?

A silicon carbide honing rock is an unpleasant tool. It’s made use of to sharpen metal edges. Blades, knives, and tools take advantage of it. Silicon carbide is an artificial material. It’s really hard. It’s also fairly sharp. These stones are available in various forms. Bench rocks are common. Pocket rocks are mobile. Installed rocks fit machines. The stone surface area holds rough fragments. These particles cut the metal. They get rid of material to develop a new edge. Silicon carbide cuts quickly. It functions well on difficult steels. It deals with carbon steel nicely. It’s likewise great for non-ferrous steels. The rock puts on down in time. It launches fresh abrasive particles. This keeps it cutting properly. Grit dimension differs a whole lot. Coarse grits get rid of steel promptly. Great grits polish the edge. Picking the appropriate grit is important. It relies on the device and work.

2. Why Grit Matters A Lot for Silicon Carbide Stones?

Grit size is vital. It establishes the stone’s feature. Crude grit stones have big bits. They reduced strongly. They get rid of steel quick. This is excellent for fixing damage. It repairs nicks and boring sides. Medium grit stones use equilibrium. They fine-tune the side after crude job. They prepare for finer honing. Fine grit stones have tiny fragments. They polish the side efficiently. They develop a lancinating finish. Using the incorrect grit creates troubles. A rock too rugged can get rid of too much steel. It can spoil the tool’s profile. A rock too fine works slowly. It battles with damaged edges. It loses time. Silicon carbide rocks often are available in certain grit arrays. Typical crude grits are around 80 to 120. Tool grits might be 180 to 400. Fine grits could be 600 and higher. Matching the grit to the job is wise. It conserves initiative. It provides much better results. Grit directly impacts the side top quality. It influences how much time the edge remains sharp. Comprehending grit makes you a far better sharpener.

3. Exactly how to Pick the Perfect Grit for Your Demands?

Selecting grit needs thought. Consider the tool’s condition initially. Is the edge badly damaged? Beginning with crude grit. A 60 or 80 grit silicon carbide stone functions well. It repairs chips swiftly. Is the edge just plain? A medium grit may suffice. Attempt 220 or 320 grit. This improves the side effectively. Do you need a sleek coating? Choose fine grit. Use 600 grit or finer. Think about the tool product. Tough steels need aggressive rocks. Rugged silicon carbide manages them. Softer steels could require finer grits. Consider the device type. Axes and machetes typically require crude stones. Kitchen area blades gain from medium to great grits. Woodworking chisels need fine ending up. Your developing approach issues as well. Hand honing offers control. You may use less grit actions. Device honing can use a progression. Beginning crude. Move to penalty. Think of your objective. Rate requires rugged grit. A mirror finish requires fine grit. Spending plan contributes as well. Acquiring numerous rocks sets you back extra. A single medium grit stone is flexible. Experience assists. Attempt different grits. See what works best for you. There’s no solitary best grit. The most effective grit fits your specific task.

4. Applications: Where Silicon Carbide Stones Luster

Silicon carbide rocks are flexible. They excel in a number of locations. Repairing damaged sides is a toughness. Their solidity cuts difficult steel fast. Getting rid of chips from an axe is simple. Fixing a nicked knife blade fasts. Honing very difficult tool steel works well. Files and drill little bits hone nicely. Honing non-ferrous metals is an additional usage. Brass, copper, and light weight aluminum devices can be developed. Silicon carbide handles them without loading up. Deburring steel parts is possible. Getting rid of sharp burrs after cutting. Harsh shaping devices works. Developing a fundamental bevel on a brand-new chisel. Area sharpening is practical. Pocket-sized silicon carbide stones are portable. They work without water or oil commonly. Dry sharpening is feasible. They are sturdy. They withstand wear far better than some rocks. They are budget-friendly. They supply great value. They are a great option for newbies. Straightforward to make use of. Effective results. Experts use them as well. For rapid supply elimination. For laborious. They enhance other rocks. Use silicon carbide for coarse job. Adhere to with better stones like aluminum oxide. They are workhorse abrasives. Trustworthy and sensible.

5. Frequently Asked Questions: Usual Inquiries Regarding Silicon Carbide Grit

People frequently have inquiries. Right here are some answers.

What grit is regular for silicon carbide rocks? They frequently are available in rugged varieties. Grits like 60, 80, 120, 220, 320 prevail. Fine grits exist yet are less constant than other stones.

Can I make use of silicon carbide for great polishing? Feasible, however not suitable. Silicon carbide stands out at crude job. For great polishing, various other stones like Arkansas or ceramic are much better. They offer a smoother coating.

Do I need oil or water with silicon carbide stones? In some cases. Some are developed for completely dry use. Others function much better with water or oil. Examine the supplier’s guidance. Making use of liquid can lower blocking. It keeps the rock cutting well.

How long does a silicon carbide stone last? Fairly long. Silicon carbide is hard. It uses gradually. It lasts longer than softer rocks. Correct treatment prolongs its life. Maintain it clean. Store it appropriately.

Are silicon carbide rocks good for blades? Yes, particularly for repair work. Taking care of harmed blades. Establishing a brand-new side. For routine honing, tool grit works. For brightening, use a finer stone after that.

Can I squash a silicon carbide rock? Yes, yet it’s tough. The rock itself is very rough. Make use of a crude diamond plate. Or make use of sandpaper on a flat surface. Flattening keeps the stone reliable.

(what grit is silicon carbide sharpening stone from dans whetstone?)

Is silicon carbide the same as carborundum? Essentially, yes. Carborundum is a common brand name. It describes silicon carbide unpleasant items.