High-Quality Silicon Carbide Products | Advanced Ceramic Solutions

The Gritty Truth: Can 1000-Grit Sanding Belts Really Sharpen Knives?

(is 1000 grit silicon carbide sanding belts good to sharpen knives?)

Knife sharpening. It’s an art, a science, and sometimes, a source of endless debate. Everyone seems to have their favorite method. Stones, steels, pull-through gadgets, even the bottom of a ceramic mug. But what about power tools? Specifically, what about using those rough, scratchy sanding belts you see on big machines? Can something designed to smooth wood or metal really put a razor edge on your kitchen knife? Today, we’re diving deep into one specific tool: the 1000 grit silicon carbide sanding belt. Is it a sharpening hero or a total zero? Let’s find out.

1. What Exactly Are 1000 Grit Silicon Carbide Sanding Belts?

Let’s break it down. First, sanding belts are just what they sound like. They are long loops of abrasive material glued onto a flexible backing. You find them on belt sanders. These machines spin the belt fast over rollers. People mostly use them for woodworking or metal shaping. They remove material quickly to shape or smooth surfaces.

Now, the grit. Grit tells you how coarse or fine the abrasive particles are. A low grit number, like 80, means big, rough particles. It cuts fast but leaves deep scratches. A high grit number, like 1000, means much smaller particles. It cuts slower and leaves a finer, smoother finish. 1000 grit sits in the medium-fine range. It’s finer than what you’d use for heavy stock removal but coarser than a polishing grit.

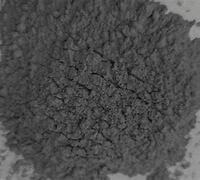

Finally, the abrasive material itself: silicon carbide. This is a very hard, man-made mineral. It’s tougher than aluminum oxide, another common abrasive. Silicon carbide excels at cutting hard materials. Think steel, glass, ceramics. It stays sharp longer than softer abrasives when cutting tough stuff. It also tends to generate less heat than some others. This matters for sharpening tools.

So, a 1000 grit silicon carbide sanding belt is a loop of tough, sharp particles glued to a belt. The particles are small enough to create a fairly fine surface. These belts are common in workshops. They are not usually marketed specifically for knife sharpening. But that doesn’t mean they can’t be used for it. We just need to understand how.

2. Why Would You Use a 1000-Grit Belt for Knife Sharpening?

Sharpening a knife involves removing metal to create a new edge. Any abrasive can do this. But why choose a 1000 grit silicon carbide sanding belt? There are a few reasons, especially for certain situations.

Speed is a big factor. Belt sanders work fast. A motor spins the belt at high speed. You hold the knife against it. Metal removal happens quickly. This is great if you have a very dull knife. Or if you need to reshape a damaged edge. It saves a lot of time compared to slow hand sharpening on stones.

The grit level is another point. 1000 grit is a good middle ground. It’s coarse enough to remove metal efficiently. Yet it’s fine enough to create a reasonably sharp edge. It won’t leave huge, deep scratches that take forever to polish out later. For many users, a 1000-grit finish is perfectly acceptable. It’s sharp enough for everyday kitchen tasks. Think slicing tomatoes or carving meat.

Silicon carbide is hard. It cuts hardened steel well. Knife steel is hard. A soft abrasive might wear down too fast. Silicon carbide holds up better. It stays effective longer on tough steels. This gives you a consistent cut.

Cost and availability matter too. These belts are common and relatively cheap. Many hobbyists already own a belt sander for other projects. Using a belt they already have makes sense. It avoids buying specialized sharpening stones or systems.

It’s not perfect for all knives. Delicate knives or expensive chef’s knives deserve finer methods. But for work knives, hunting knives, or quick tune-ups? A 1000 grit silicon carbide belt can be a practical choice. It gets the job done fast.

3. How Do You Actually Use Them to Sharpen a Knife?

Okay, you’re convinced to try it. How do you use a 1000 grit silicon carbide sanding belt on a knife without ruining it? It requires care and the right technique. Belt sanders are powerful. Mistakes happen fast.

Safety first. Always wear safety glasses. Tiny metal particles fly everywhere. Good gloves are smart too. Protect your hands. Secure the belt sander firmly. You don’t want it moving around.

The belt must be clean. Old belts loaded with wood dust or metal filings won’t cut steel well. Use a new belt or clean an old one with a rubber belt cleaner. Make sure the belt is tracking straight on the sander. It shouldn’t wobble side to side.

Now, the knife. You need to hold it steady. This is the hardest part. Do NOT press the knife flat against the belt. This grinds away the whole blade face. You ruin the knife’s geometry. You only want to sharpen the very edge.

Instead, you need to recreate the knife’s existing edge angle. Hold the knife so only the bevel touches the belt. Imagine the angle the knife was originally sharpened at. Usually, it’s around 15 to 20 degrees per side. You need to match this angle. Hold the knife firmly. Rest your fingers on the sander’s table or a support for stability.

Move the knife smoothly along the belt. Don’t hold it in one spot. Keep it moving to avoid overheating one area. Overheating can ruin the knife’s temper. It makes the steel soft. Apply very light pressure. Let the belt’s abrasives do the work. You only need a few seconds of contact per side.

Check your progress often. Wipe the edge clean. Feel for the burr. The burr is a tiny lip of metal pushed over to the opposite side. It forms when you’ve sharpened one side enough. Once you feel the burr along the whole edge, switch to the other side. Sharpen that side until you raise a burr again. Then, you can move to finer grits or strop to remove the burr and polish the edge. But with just the 1000 grit silicon carbide belt, you can stop here for a working edge. It takes practice to get the angle right and avoid mistakes. Go slow.

4. What Knives or Tools Are They Best Used On?

A 1000 grit silicon carbide sanding belt isn’t ideal for every knife. It’s a bit aggressive for fine polishing. But it shines in several applications.

It’s excellent for fast edge restoration. Think about knives that see hard use. Hunting knives used for field dressing. Pocket knives that open boxes daily. Machetes clearing brush. These tools get dull fast. They often get nicked or damaged. Using a belt sander with a 1000 grit silicon carbide belt lets you fix the edge quickly. You can remove nicks and reset the bevel in minutes. It brings a badly worn knife back to functional sharpness fast.

It works well for tools beyond knives. Think scissors, axes, hatchets, chisels, even some woodworking plane blades. Any tool steel edge that needs reshaping or significant material removal benefits. The speed of the belt sander makes the job much easier. The 1000 grit leaves a finish sharp enough for these tools to work well.

Cheaper, softer steel knives handle it fine. Many common kitchen knives aren’t super hard. They don’t need a mirror polish. A sharp edge from a 1000 grit silicon carbide belt is better than a dull one. It’s a practical solution for everyday sharpening needs.

It’s less ideal for high-end kitchen knives. Japanese chef’s knives with very hard steel and thin edges require precision. The belt sander method is too crude. You risk overheating the thin edge. You might grind away too much metal. These knives deserve careful hand sharpening on water stones. The same goes for delicate fillet knives or razors. The power and coarseness of a belt sander are overkill.

For tough, utilitarian blades and tools? A 1000 grit silicon carbide sanding belt is a powerful ally. It gets them back in action fast.

5. FAQs: Answering Your Burning Questions

Let’s tackle some common questions about using 1000 grit silicon carbide sanding belts for sharpening.

Will it ruin my knife? It can, if you do it wrong. Applying too much pressure, holding the wrong angle, or staying in one spot too long causes problems. You can overheat the steel, grind away too much metal, or ruin the blade profile. Done carefully with the right technique, it’s safe for many knives.

Is 1000 grit fine enough? It depends. For a working edge on most knives, yes. It won’t be a mirror polish. It won’t effortlessly glide through paper like a laser. But it will slice tomatoes, cut rope, and perform most tasks well. If you want a finer edge, you can progress to higher grit belts or finish on a stone or strop.

Silicon carbide vs. other abrasives? Silicon carbide is very hard. It cuts hardened steel efficiently. Aluminum oxide is softer and wears faster on hard steel. Ceramic abrasives are also hard but often finer. For a 1000 grit belt, silicon carbide is a good choice for knives. It lasts well.

Can I use any belt sander? Mostly, yes. Big industrial sanders work. Smaller benchtop models work too. The key is stability. You need to hold the knife steady against the moving belt. Sanders with a flat platen (the backing plate behind the belt) are best. They provide solid support. Avoid sanders where the belt runs over an unsupported roller. It’s too bouncy for precise sharpening.

(is 1000 grit silicon carbide sanding belts good to sharpen knives?)

Do I need special sharpening belts? Not necessarily. Regular 1000 grit silicon carbide sanding belts sold for general use can work. However, some companies make belts specifically designed for sharpening. These might have special backings or abrasive blends. They can be better, but standard belts often do the job fine. Just ensure they are clean and sharp.