High-Quality Silicon Carbide Products | Advanced Ceramic Solutions

Title: Silicon Carbide in Ethanol: Unboxing the Power Pair .

(is silicone carbide in ethanol)

1. Just What is Silicon Carbide in Ethanol? .

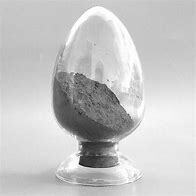

Silicon carbide, typically called SiC or carborundum, is an incredibly hard artificial material. Think of it like super-hard sand. Ethanol prevails alcohol, the kind you find in beverages or hand sanitizer, yet very pure for technical uses. Put them with each other, and you obtain silicon carbide particles floating or blended within ethanol. This mixture is a specific slurry or suspension. Individuals in some cases puzzle ‘silicone’ (like rubber) with ‘silicon’ (the component). Silicon carbide originates from silicon and carbon. It looks like dark grit or great powder. Its key attributes are amazing hardness, terrific heat resistance, and excellent thermal conductivity. Ethanol works as the fluid carrier. It holds the SiC bits. This fluid medium makes the mixture usable for numerous jobs. The mix develops a flexible functioning fluid. It’s not just a basic mix; it’s a functional material system.

2. Why Mix Silicon Carbide with Ethanol? Why Not Water or Another Thing? .

Selecting ethanol over other liquids like water isn’t random. It has strong benefits. Water appears very easy, yet it triggers problems. Silicon carbide can respond slowly with water over time. This reaction could alter its surface or develop undesirable deposits. Ethanol avoids this. It’s chemically a lot more steady with SiC. Ethanol likewise vaporizes easily and rapidly. After making use of the SiC/ethanol mix, the ethanol disappears quickly. It leaves very little deposit. This is essential for tasks needing super clean surfaces, like polishing integrated circuits. Water leaves areas and natural resource. Security is one more aspect. While ethanol is combustible, it deals with differently than some harsh solvents. It’s much less poisonous than choices like acetone or toluene. Ethanol additionally has excellent wetting buildings. It helps the SiC particles spread out equally and stick well to surface areas. This improves efficiency in work like polishing or covering. Its low thickness helps particles move easily. Overall, ethanol supplies a cleaner, much safer, and usually more reliable carrier for silicon carbide than numerous options.

3. Exactly how Do You Really Deal With Silicon Carbide in Ethanol? .

Obtaining the mix right issues. It starts with the silicon carbide powder. The bit dimension is vital. Better grit brightens smoother; coarser grit cuts faster. The powder requires to be pure and regular. Pure ethanol, like lab-grade or denatured ethanol, is made use of. Blending them isn’t just dumping powder in fluid. Achieving a secure suspension is key. The hefty SiC bits tend to sink promptly. To prevent this, consistent stirring or agitation is usually needed during usage. Often, special additives called dispersants or surfactants are used. These help maintain the particles separated and drifting evenly. Consider them like a covering that stops the grains from clumping and sinking. Ultrasonic baths are an effective device. Sound waves blast via the mixture. This breaks up clumps and spreads fragments uniformly. Grating the mixture can likewise aid. It grinds fragments smaller sized and disperses them much better. Avoiding water contamination is essential. Also a little water can destroy the mix’s stability and performance. Containers has to be sealed tight. Humidity needs managing. The blend is normally made fresh or stored thoroughly for brief periods. Using it involves using it properly– spraying, dipping, or streaming it over a surface with the right devices.

4. Where Do We Utilize This Silicon Carbide and Ethanol Combo? Applications Radiate .

This duo deals with laborious throughout industries. Accuracy polishing is a major one. SiC in ethanol slurry is amazing for washing and brightening very tough products. Think sapphire windows, advanced porcelains, and silicon wafers for electronics. The ethanol cleans up as it brightens, leaving no water spots. Surface area prep work is an additional large area. Before painting or finish metal, the surface must be harsh and clean. SiC/ethanol blasting does this wonderfully. It engraves the surface area perfectly. The ethanol evaporates fast, leaving the metal prepared promptly, no drying out required. It’s cleaner than sandblasting with water or oil. In materials scientific research labs, it’s a workhorse. Scientists use it to prepare samples for microscopes. They require surfaces flawlessly smooth and ultra-clean. The ethanol service provider ensures no deposit interferes with their analysis. Slim film coating procedures sometimes utilize it as well. The slurry helps develop specific structures on substrates prior to coating. Emerging usages are popping up. Some 3D printing techniques check out SiC suspensions in ethanol for printing ceramic parts. Scientists check out it for making advanced compounds and thermal pastes. Its ability to deal with heat makes it interesting for electronics cooling down.

5. Silicon Carbide in Ethanol: Your Inquiries Responded To (Frequently Asked Questions) .

Is this blend safe? Take care of with care. Ethanol is very combustible. No stimulates, no open fires, good air flow are outright musts. Use gloves and eye protection. SiC dirt is a toxic irritant; do not breathe it in. Review safety sheets.

Will the bits simply sink to the base? Yes, they work out over time. That’s normal. You need to mix or perturb the blend well ideal prior to you use it. Ultrasonic bathrooms assist a lot for tiny volumes. Constant blending systems help bigger configurations.

Can I utilize normal massaging alcohol? Perhaps, however beware. Rubbing alcohol usually consists of water and additives (like bitterants). These can ruin the mix. They create bad dispersion, deposit, or reactions. Use pure ethanol (like lab quality or particularly denatured ethanol) for trustworthy results.

Is it expensive? High-purity silicon carbide powder isn’t affordable. Pure ethanol costs greater than water. Nonetheless, the efficiency benefits often warrant the cost. Cleaner outcomes, faster drying, less remodel, and much better surface area quality conserve money and time in essential applications.

(is silicone carbide in ethanol)

Water helps some things. When should I definitely pick ethanol? Pick ethanol when you need: an extremely clean, residue-free surface; collaborating with products sensitive to water; faster drying out times; or staying clear of possible slow reactions in between SiC and water. If price is the biggest element and absolute cleanliness isn’t essential, water-based slurries might be an option, yet understand the trade-offs.