High-Quality Silicon Carbide Products | Advanced Ceramic Solutions

PRODUCT PARAMETERS

Description

Overview of Silicon Carbide Powder

Silicon carbide (SiC) powder is a high-performance ceramic material composed of silicon and carbon. Known for its exceptional hardness, thermal stability, and wear resistance, SiC powder is widely used in abrasives, cutting tools, refractory materials, and advanced technological applications like semiconductors and electric vehicle components.

Features of Silicon Carbide Powder

Exceptional Hardness: One of the hardest known materials, second only to diamond, making it ideal for abrasive and cutting applications.

Thermal Stability: High resistance to thermal shock and can withstand extreme temperatures, enhancing its utility in refractory and high-temperature environments.

Chemical Inertness: Resistant to most chemicals, including acids and alkalis, ensuring durability in harsh conditions.

Wear Resistance: Excellent wear resistance properties make it suitable for demanding mechanical applications.

Electrical Conductivity: Depending on the purity and doping levels, SiC can exhibit varying degrees of electrical conductivity, useful in electronics.

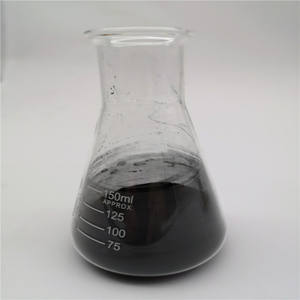

(Pakistan Sic 97.8% Black Silicon Carbide Powder )

Specifications of Pakistan Sic 97.8% Black Silicon Carbide Powder

Pakistan Sic 97.8% Black Silicon Carbide Powder is a high-performance industrial abrasive. It originates from Pakistan. This material is really difficult. It is extremely sharp. Its pureness level is 97.8%. This high pureness makes it reputable. It functions well in laborious. The powder is black. It has sharp, angular grains. These grains cut materials efficiently. They put on down slowly. This powder lasts a very long time. Its hardness is near diamond. This solidity benefits grinding. It benefits reducing. It benefits sandblasting.

The powder can be found in various grit sizes. You can obtain crude grits. You can get great grits. Rugged grits remove product quickly. Great grits give smooth finishes. This powder is tough. It stands up to damaging. It keeps its form under stress. It deals with high temperatures well. This serves in lots of industries. Factories utilize it for grinding wheels. They utilize it for cutting devices. They utilize it for rough blasting media. It reduces steel. It reduces stone. It reduces glass. It reduces ceramics. It cleans surface areas. It prepares surfaces for painting. It brightens surface areas.

This silicon carbide powder is chemically secure. It does not react easily. It operates in acids. It works in alkalis. It operates in high warm. This security is necessary. It makes sure constant performance. The powder is a great conductor of warm. This assists in some applications. It protects against heat damage. It carries warmth away from the workplace. Pakistan Sic 97.8% Black Silicon Carbide Powder is flexible. It is cost-effective. It gets the job done well. It is a popular choice worldwide. You must keep it in a completely dry location. Maintain it away from wetness. Wetness can influence its circulation. Dampness can affect its efficiency.

(Pakistan Sic 97.8% Black Silicon Carbide Powder )

Applications of Pakistan Sic 97.8% Black Silicon Carbide Powder

Pakistan Sic 97.8% Black Silicon Carbide Powder is a high-grade product. It comes from Pakistan. This powder is very difficult. It’s practically as hard as diamond. This makes it solid versus wear. It also manages extreme heat effectively. It stays stable at high temperatures. This powder is really pure. It’s 97.8% silicon carbide. This high purity matters for requiring work.

This powder functions excellent for abrasives. Factories use it in grinding wheels. They utilize it in sandpaper. They utilize it in cutting tools. It cuts metals effectively. It grinds porcelains smoothly. It brightens stone properly. It works much faster than many various other abrasives. It lasts longer too. This saves cash.

It’s important for refractories. Refractories line furnaces. They line kilns. They need to withstand extreme heat. Including this powder makes refractories harder. It aids them last longer under warm anxiety. This reduces furnace downtime. It reduces maintenance prices.

The metallurgy sector utilizes this powder. Manufacturing facilities add it to thaw iron. It helps eliminate oxygen. This makes the iron more powerful. It boosts the iron’s quality. It helps control the carbon material. This is crucial permanently castings.

It serves various other sectors as well. Ceramic manufacturers use it. It enhances ceramic components. Electronics business use it. It aids make sure elements. It brightens semiconductors. It cuts wafers precisely.

This black silicon carbide powder is tough. It takes care of warmth better than several products. It costs less than synthetic rubies. It carries out far better than usual abrasives like quartz. Pakistan offers a great resource. The 97.8% pureness guarantees trusted efficiency. Customers get regular results.

Company Introduction

Welcome to It-Chuiko, a premier international supplier of high-quality silicon carbide powder and silicon carbide ceramics. Our products are renowned for their exceptional hardness, thermal stability, and wear resistance, making them ideal for abrasives, cutting tools, refractory materials, and advanced semiconductor applications. We serve a diverse range of industries, including automotive, aerospace, and electronics, with a commitment to quality and innovation. With state-of-the-art production facilities and rigorous quality control, we ensure that our customers receive superior products tailored to their specific needs. Partner with us for reliable, high-performance materials that drive your business forward.

If you have any questions, please feel free to contact us(nanotrun@yahoo.com).

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Pakistan Sic 97.8% Black Silicon Carbide Powder

Pakistan Sic 97.8% Black Silicon Carbide Powder is a high-performance abrasive material. Customers often ask these questions.

What exactly is this product?

This is a very hard, sharp powder. It’s made from silicon and carbon. The Sic 97.8% means it’s almost pure silicon carbide. The “black” refers to its color. It’s crushed into fine grains.

Where does it come from?

The powder originates from Pakistan. Pakistan produces good quality silicon carbide raw material. This powder is processed and refined there. It meets international quality standards.

Why is the 97.8% purity important?

Higher purity means better performance. Impurities weaken the material. 97.8% purity ensures hardness and sharpness. It makes the powder last longer. It cuts well. It grinds efficiently. This level is ideal for demanding industrial tasks.

What are the main uses?

This powder is very versatile. It’s perfect for grinding and cutting hard materials. Factories use it for polishing stone and metal. It works in sandblasting to clean surfaces. The foundry industry uses it for mold linings. Ceramic manufacturers add it to strengthen products. It’s also used in refractory materials for high heat.

Is it safe to handle?

Handle this powder carefully. Wear gloves. Wear a dust mask. Avoid breathing in the dust. It can irritate skin and lungs. Keep it away from eyes. Store it in a dry place. Keep containers sealed. Follow standard industrial safety practices.

This powder offers reliable performance for tough jobs. Its high purity makes it a valuable industrial material.

(Pakistan Sic 97.8% Black Silicon Carbide Powder )

REQUEST A QUOTE

RELATED PRODUCTS

Factory of Silicon Carbide Powder with good quality/Black Carborundum powder

Beta Grayish Green Cubic Superfine SiC Nanoparticle Silicon Carbide Powder for Polymer

Silicon Carbide Powder

High Strength Kiln Heat Insulation Silicon Carbide And Carbon Refractory Slurry for Thermal Plant Stack Furnaces

High mechanical strength silicon carbide free from noise and air pollution SCR type SiC heating element silicon carbide rod