High-Quality Silicon Carbide Products | Advanced Ceramic Solutions

PRODUCT PARAMETERS

Description

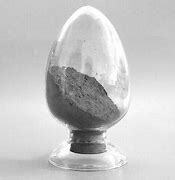

Overview of Silicon Carbide Powder

Silicon carbide (SiC) powder is a high-performance ceramic material composed of silicon and carbon. Known for its exceptional hardness, thermal stability, and wear resistance, SiC powder is widely used in abrasives, cutting tools, refractory materials, and advanced technological applications like semiconductors and electric vehicle components.

Features of Silicon Carbide Powder

Exceptional Hardness: One of the hardest known materials, second only to diamond, making it ideal for abrasive and cutting applications.

Thermal Stability: High resistance to thermal shock and can withstand extreme temperatures, enhancing its utility in refractory and high-temperature environments.

Chemical Inertness: Resistant to most chemicals, including acids and alkalis, ensuring durability in harsh conditions.

Wear Resistance: Excellent wear resistance properties make it suitable for demanding mechanical applications.

Electrical Conductivity: Depending on the purity and doping levels, SiC can exhibit varying degrees of electrical conductivity, useful in electronics.

(Hot high purity Advanced ceramics Silicon carbide powder whisker (Beta-SiC) CAS 409-21-2)

Specifications of Hot high purity Advanced ceramics Silicon carbide powder whisker (Beta-SiC) CAS 409-21-2

Hot high purity Advanced porcelains Silicon carbide powder hair (Beta-SiC), CAS 409-21-2, is a specialized material designed for high-performance commercial applications. This item includes beta-phase silicon carbide in whisker form, characterized by phenomenal mechanical strength, thermal stability, and chemical resistance. The purity degree goes beyond 99.9%, decreasing pollutants that could influence efficiency in vital settings. Particle dimensions vary from 0.5 to 5 micrometers, with whisker sizes flexible between 10 and 200 micrometers to satisfy details requirements.

The material is excellent for enhancing composites in aerospace, vehicle, and protection industries. It enhances fracture durability in ceramic matrix compounds, metal alloys, and polymer-based systems. Its high thermal conductivity (approximately 120 W/m · K) makes sure reliable warmth dissipation in digital elements. The whisker structure provides anisotropic properties, improving load-bearing capacity in high-stress applications.

Beta-SiC whiskers operate successfully in temperature levels as much as 1600 ° C under inert problems. They stand up to oxidation in air as much as 1200 ° C, keeping architectural integrity in extreme settings. The product exhibits reduced thermal expansion, reducing risks of fracturing during rapid temperature adjustments. Electrical properties consist of semi-conductivity, suitable for specialized electronic gadgets needing thermal and electrical monitoring.

Surface area therapies are offered to enhance compatibility with matrices like light weight aluminum, titanium, or epoxy. Customizable surface finishes improve dispersion and bonding, ensuring consistent reinforcement in final products. The powder is provided in secured, moisture-proof containers to stop contamination. Storage space recommendations consist of amazing, completely dry conditions away from direct sunshine.

Safety and security protocols need taking care of with safety devices to avoid breathing or skin get in touch with. Beta-SiC hairs adhere to worldwide requirements for unsafe materials, needing appropriate disposal approaches. Applications span innovative porcelains, rubbing products, wear-resistant finishes, and energy storage space systems. Technical support is attended to integration right into customized formulas, ensuring ideal efficiency.

The product goes through extensive quality assurance, including XRD, SEM, and wager analysis. Qualifications consist of ISO 9001 and material security information sheets (MSDS). Batch-specific examination records guarantee uniformity in fragment dimension, morphology, and chemical structure. Lead times differ based on order volume and customization requirements.

(Hot high purity Advanced ceramics Silicon carbide powder whisker (Beta-SiC) CAS 409-21-2)

Applications of Hot high purity Advanced ceramics Silicon carbide powder whisker (Beta-SiC) CAS 409-21-2

High-purity sophisticated porcelains silicon carbide powder whisker (Beta-SiC) with CAS 409-21-2 serves vital roles across industries. This material incorporates high thermal conductivity, severe hardness, and chemical stability. These characteristics make it optimal for requiring atmospheres.

In aerospace design, Beta-SiC whiskers strengthen composite materials. Elements like wind turbine blades and thermal barrier take advantage of added toughness and warm resistance. This boosts performance while reducing weight. The outcome is fuel-efficient aircraft capable of dealing with high-stress problems.

The automotive industry makes use of Beta-SiC in brake systems and engine parts. The material stands up to intense friction and temperatures. This expands part life-span and guarantees integrity under hefty use. Electric cars utilize it in battery thermal monitoring systems. It aids regulate warmth accumulation throughout quick charging.

Electronic devices makers count on Beta-SiC for semiconductor tools. Its capacity to take care of high voltages and frequencies makes it ideal for power electronics. Tools like diodes and transistors operate effectively in severe conditions. The material additionally appears in warm sinks for LED illumination. It protects against overheating and maintains illumination.

Power applications consist of nuclear reactors and solar energy systems. Beta-SiC stands up to radiation damages and keeps structural stability in reactor cores. Solar inverters utilize it to take care of high electrical lots. This sustains stable power conversion from panels to grids.

The chemical industry utilizes Beta-SiC in destructive atmospheres. Activator linings and pump parts withstand acids and antacids. This decreases equipment wear and downtime. Wear-resistant coverings made with Beta-SiC shield industrial machinery. They decrease disintegration in unpleasant procedures.

Clinical technology uses Beta-SiC in sophisticated imaging devices. Its stability makes sure exact efficiency in MRI devices and X-ray systems. Research continues right into new usages for this versatile material.

Company Introduction

Welcome to It-Chuiko, a premier international supplier of high-quality silicon carbide powder and silicon carbide ceramics. Our products are renowned for their exceptional hardness, thermal stability, and wear resistance, making them ideal for abrasives, cutting tools, refractory materials, and advanced semiconductor applications. We serve a diverse range of industries, including automotive, aerospace, and electronics, with a commitment to quality and innovation. With state-of-the-art production facilities and rigorous quality control, we ensure that our customers receive superior products tailored to their specific needs. Partner with us for reliable, high-performance materials that drive your business forward.

If you have any questions, please feel free to contact us(nanotrun@yahoo.com).

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Hot high purity Advanced ceramics Silicon carbide powder whisker (Beta-SiC) CAS 409-21-2

What is Beta-SiC powder whisker?

Beta-SiC powder whisker is a high-purity synthetic material made of silicon carbide. It forms a needle-like structure. The beta phase refers to its cubic crystal structure. It is used in advanced ceramics for industrial applications due to its strength and heat resistance.

What are the main properties of Beta-SiC?

Beta-SiC has high thermal conductivity. It resists extreme temperatures, corrosion, and wear. It is chemically stable. The material has low thermal expansion. These traits make it suitable for harsh environments.

Where is Beta-SiC powder whisker commonly used?

It is used in aerospace components like turbine blades. Electronics use it for heat sinks. Automotive industries apply it in brake systems. It reinforces composite materials. Research labs use it for high-performance experiments.

Is Beta-SiC powder whisker safe to handle?

The powder is non-toxic but requires careful handling. Avoid inhaling particles. Use protective gear like masks and gloves. Store it away from moisture. Follow local disposal regulations.

How should Beta-SiC powder be stored?

Keep it in a dry, cool place. Use airtight containers to prevent contamination. Avoid exposure to direct sunlight. Ensure the storage area is well-ventilated. Check containers regularly for damage.

(Hot high purity Advanced ceramics Silicon carbide powder whisker (Beta-SiC) CAS 409-21-2)

REQUEST A QUOTE

RELATED PRODUCTS

Green silicon carbide abrasive carborundum powder GC glass polishing powder

professional silicon carbide CAS 409-21-2

China Factory Supply CF320# black silicon carbide sand blast black sic powder for blasting

MZ-M Factory supply High purity green silicon carbide powder 20-280 mesh green silicon carbide powder 1.5-40um

Green Powder Silicon Carbide Grinding Powder Black Micro Powder For Industry Kiln